Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() April 12, 2022

April 12, 2022

The biggest feature of the cement industry is high energy consumption and high consumption of metal materials. Every year, more than 2 million tons of metal materials are consumed due to wear and tear in my country. The two major modules are grinding balls and lining plates. 55% of wear consumables, and lining consumables are also as high as 11%. The most important thing is that cement is one of the most important building materials. The content of chromium has a great impact on the human body and the environment. The state has also issued mandatory standards for implementation. Therefore, finding a high-quality material can reduce energy consumption, reduce energy consumption, and reduce energy consumption in the cement industry. It is of great significance to reduce consumables and be healthy and green.

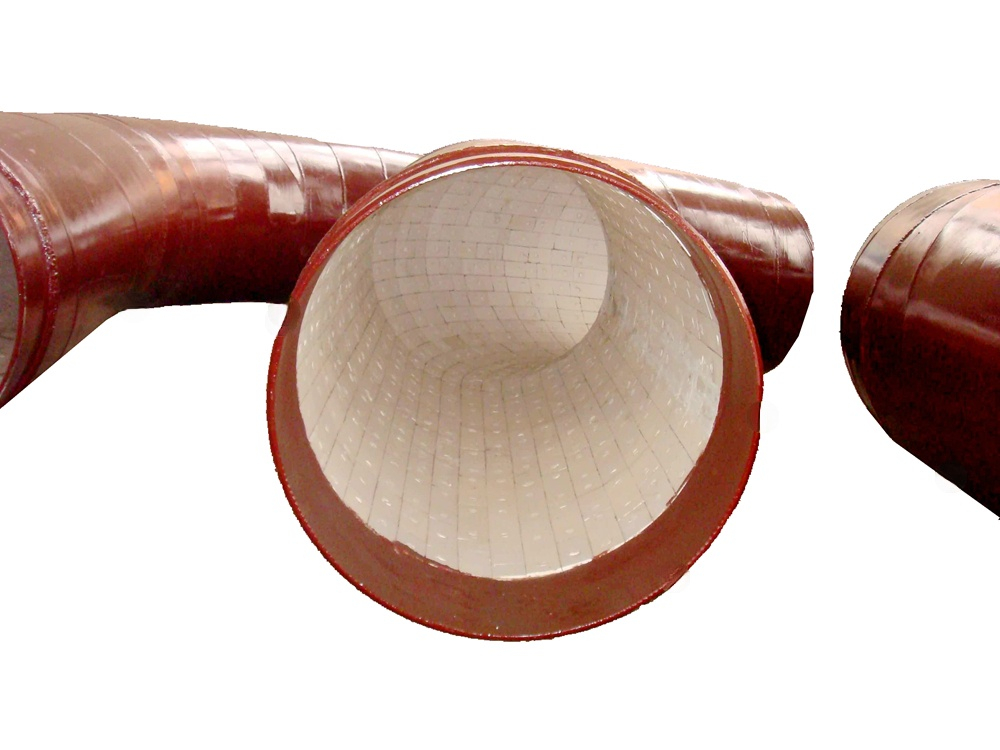

Wear-resistant ceramic materials are special ceramics with alumina as the main component, which will show different characteristics according to the content of alumina and additives. When the content of alumina reaches more than 90%, it can be called corundum ceramics, Rockwell The hardness is above 85, second only to diamond, and it is an ideal material to replace high-chromium cast iron.

Although alumina wear-resistant ceramics have high hardness, they are also relatively brittle and are prone to cracking and breaking during the cement grinding process. In order to solve this problem, we added zirconia to alumina to increase the toughness, and made new ceramic grinding balls for cement grinding and ZTA ceramic lining plates, which greatly reduced the consumption of electric energy and metal materials, and also effectively solved the problem of cement grinding. The problem of high chromium content.

In recent years, the use of wear-resistant ceramics to replace high-chromium cast iron grinding balls, steel sections, grinding bodies, lining plates, etc. has been verified in the practical application of white cement and colored cement, and the grinding ability and energy saving and consumption reduction have been highly recognized by users.

The above is the Why does the cement industry use Ceramic Liners on a large scale? we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.