Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() April 01, 2022

April 01, 2022

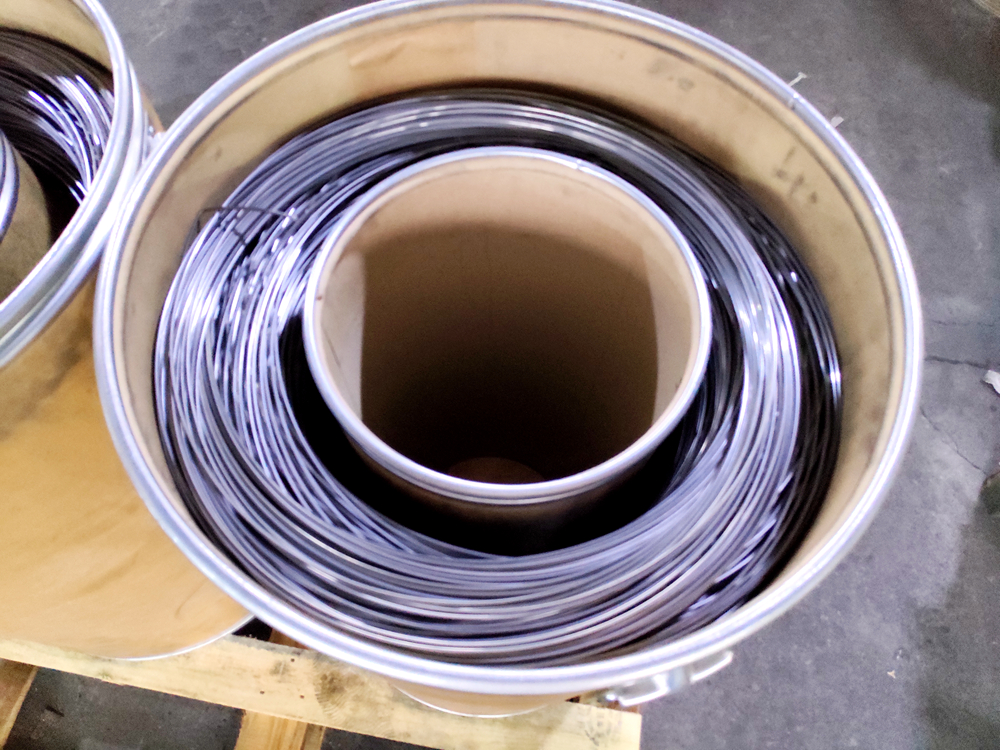

The surfacing Composite Wear Plate is based on ordinary Steel Plate, and a layer of chromium carbide is surfacing on its surface to make the steel plate have higher strength. Therefore, the quality of the surfacing Wear Plate is mainly determined by the Welding Wire and the surfacing process. decided. There are many detailed classifications of wear-resistant welding wire. First of all, it can be divided into single-layer welding wire, double-layer welding wire and multi-layer welding wire. From the use category, it can be divided into various repair wires and gas shielded wires. High-quality welding wire has smooth wire feeding, stable arc and uniform diameter. The welding wire spatter is small, the smoke is small, and the deposition efficiency is high. High-quality welding wire basically each package of welding wire is a whole wire, without seams. The welding wire with the above characteristics is high-quality welding wire.

Welding wire is divided according to thickness, there are several specifications, 1.2mm, 1.6mm, 2.4mm, 2.8mm and 3.2mm. Different specifications of welding wire have different hardness. Okay. The content of carbon and chromium determines the hardness of the welding wire, the carbon content of the basic welding wire is about 3.0-5.0, and the chromium content is between 15-40. After high-quality welding wire surfacing, the butt welding layer on the surface should have good impact resistance, and it is not easy to fall off. The welding wire can also be subdivided in more detail according to different industries. For example, some manufacturers, the welding wire can be subdivided into cement vertical mill surfacing welding wire, roll surfacing welding wire, extrusion roller surfacing welding wire, star wheel for different machinery. Repair wire and other specific classification. The gas shielded welding wire can also be subdivided into impact resistant welding wire, high temperature resistant welding wire, gas shielded repair welding wire, and welding wire containing various special elements.

In the production of surfacing wear plates, the welding plate platform is very important. Now the advanced welding plate platforms are fully automatic multi-head platforms. The multi-head platform has higher welding efficiency than the single-head platform. The surfacing wear-resistant plate is not easy to fall off the welding layer, and the flat plate is bent greatly. Moreover, the new welding plate platform has a high level of automation, which can control the start, stop and height of each welding gun, and can realize the function of continuous welding at break points. The welded bimetal composite wear-resistant plate should have uniform surface hardness, flat surface and fine cracks.

In addition, the surfacing process can not only produce bimetal wear-resistant plates, but also can use wear-resistant pipe surfacing equipment to perform surfacing welding in steel pipes to produce surfacing wear-resistant plates.

The above is the Guidance to production of wear plate we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.