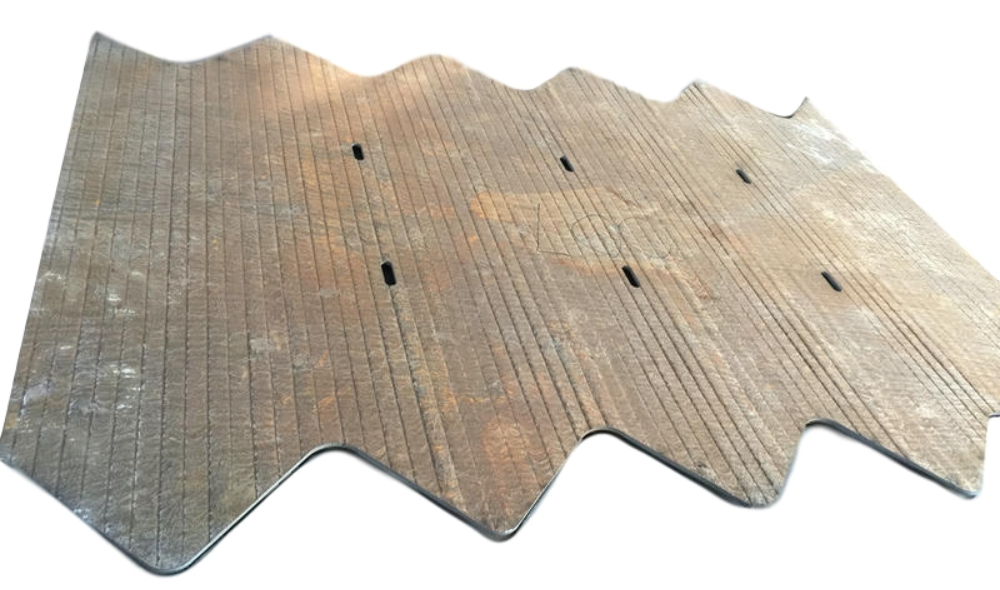

Relying on its abrasion resistance and excellent strength, HP Truck Body Liners are widely being applied as good wear solution

We can design and build Chutes for many applications where need to solve wear problem. We specialize in the production of our own HP chromium carbide plate. However, we can also make chutes from hardened steel such as mild steel, stainless steel and AR steel.

Feature

1.High wear resistance

2.12-20 times higher than common plate

3.5-10 times than low alloy Steel Plate

4.2-3 times than high chromium cast iron plate

Our service

1. Produce qualified wear resistant parts

2. Design and installation of boltless mill liners

3. Under certain working conditions, the mill liner material selection consulting service will be realized for a longer time service life

4. Grinding machine production and fineness improvement consulting services.

5. We can provide OEM / ODM to our customers.

The processes at most mines involve a wide spectrum of impact, abrasion, erosion, adhesion and corrosion that require engineered hardfacing solutions for effective wear protection. The equipment being affected ranges from large earth excavators to crushers to conveyors to pumps and valves. Mining operations extract mineral raw materials on a truly impressive scale in terms of quantities and material stresses. Moreover, they must handle the increasingly problematic overburden, which as waste material has no value but represents a major factor in the wear of plant components.

Plant maintenance personnel are constantly working to resolve issues with equipment that no longer works as efficiently as it should, or has broken down and must be replaced. With the increased economic pressures impacting the mining industry in recent years, mining operations must plan a more sustainable approach to more efficient operations with an eye towards reduced maintenance expenditures whenever possible. HP Wear Plate offers a suite of powerful engineered hardfacing solutions in all areas of mining and earthmoving activities. Following are a few examples where HP Wear Plate anti-wear solutions are regularly offered:

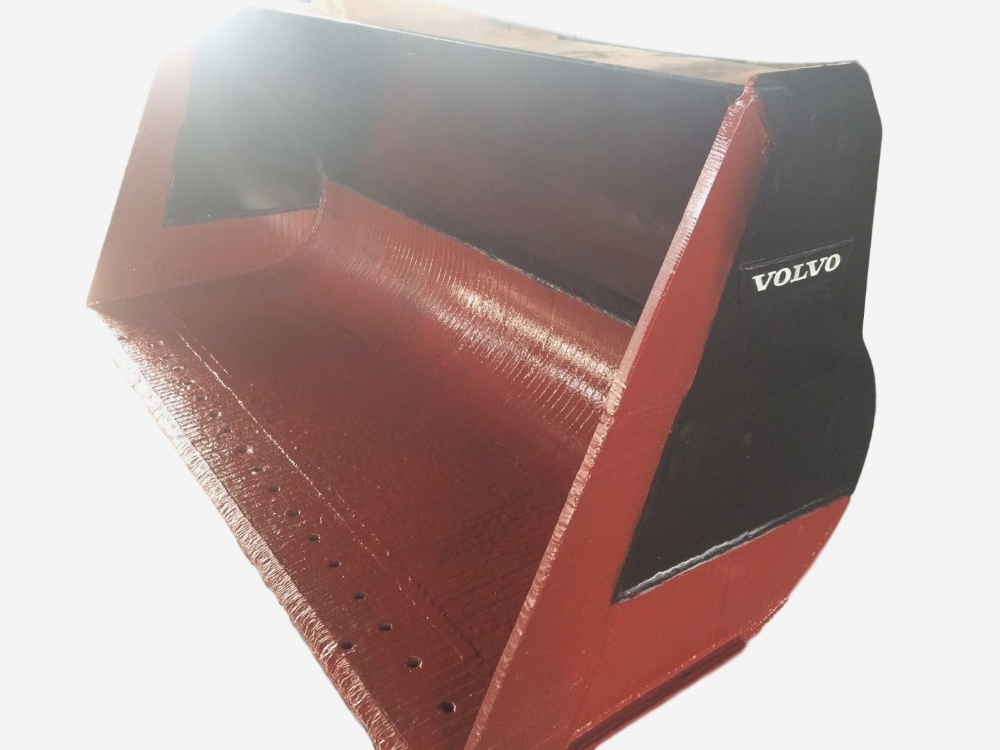

· Heavy-duty opencast mining equipment: Buckets, conveyor belts, shovel loaders, discharge chutes, material slides.

· Mining equipment – surface excavators, earth-moving machines, bucket chain excavators, stackers, front loaders, loader shovels, dragline bucket liners etc.

· Conveyors – screw feeders, material slides, linings of chain conveyors, sides and scrapers of belt conveyors.

· Crushing & screening – crusher body liners, hammers, Hopper Liners, chute liners, screening deck plates, vibro-feeders, cone crushers, breaker plates.