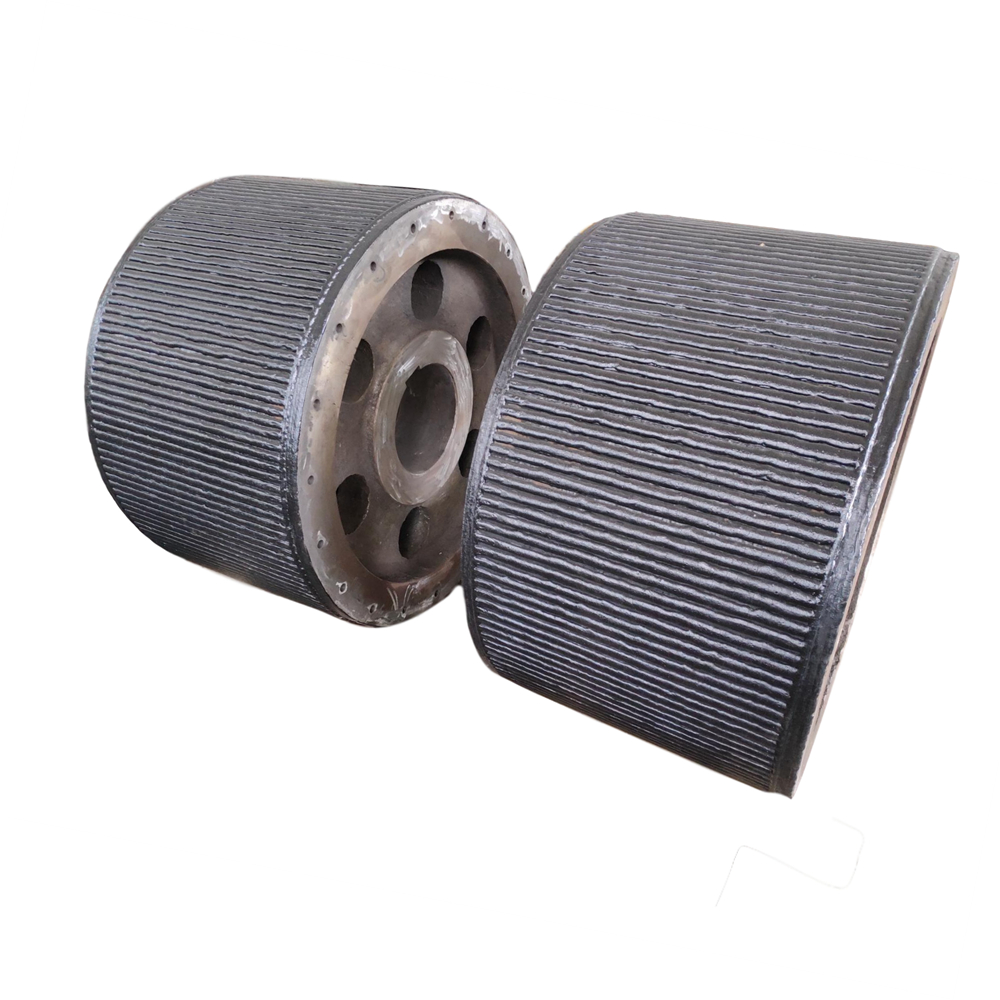

Welding Recondition is the best way to reduce cost through increase working life of your equipment. Take Vertical Roll Mill for example, the Coal Vertical Roll Mill (VRM) is an air scanning, medium speed vertical mill with an integrated classifier. It pulverizes coal by applying a hydraulically loaded grinding pressure through three grinding rolls to a rotating bed of coal. The grinding pressure can be adjusted to take into account changes in coal grindability and desired product fineness.

Working principle

The raw material is uniformly fed through the feeder at the bottom of the hopper, and then raised to a suitable height by the bucket elevator, and then sent to the mill through the feeding pipe for grinding, and the ground material enters the powder classifier and is produced by the hot air furnace. Hot air, at the same time dry and grade the material, the unqualified material is poured into the grinding, the qualified fine powder is sent to the powder collector, and then transported to storage. Through the conveyor.

Application

Can be widely used in cement, power, metallurgy, chemical, non-metallic minerals and other industries. It is used to grind granular and powdered materials into powders with the required fineness.

Introduction

It can cover the grinding machine table of various sizes and styles. We can rebuild the table internally or on site according to your needs. We also offer cast steel table replacement and a suitable overlapping section to ensure fit.

Feature

* Longer use time and lower maintenance costs

*Optimal production efficiency

*save costs

*customized product

* Environmental protection

Our service

We specialize in custom high temperature wear resistant products to improve the service life of various mechanical settings.

We are committed to customer satisfaction and high performance. We insist on providing the highest precision at the most fair price with quality products and providing the best service to all our customers.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.