Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

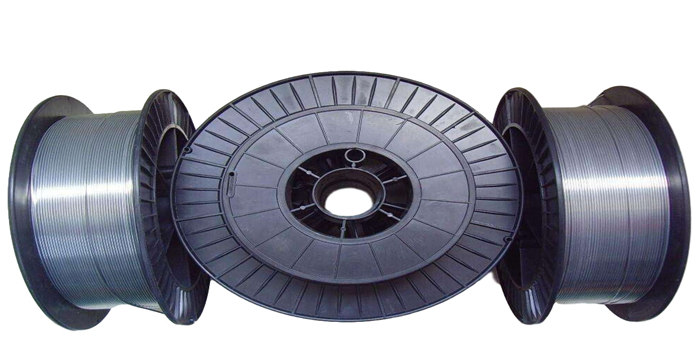

FCAW Welding Wire is kind of Open Arc Welding Wire. According to the applications of surfacing Alloy Welding Wire, the commonly used surfacing Alloy Welding wire can be divided into the following types.

1) Corrosion-resistant surfacing welding, also known as cladding surfacing welding, is a surfacing method in which a certain thickness and a corrosion-resistant alloy layer are deposited on the working surface to prevent the workpiece from corroding during operation.

2) Wear-resistant surfacing, Niobium Carbide Welding Wire can prevent the surface of the workpiece from being worn during the working process, to obtain an alloy layer with certain hardness and special properties on the surface of the workpiece, and to prolong the service life of the workpiece.

3) When surfacing the transition layer and repairing dissimilar materials by surfacing, ESAB Welding Wire prevents the adverse effect of the composition of the base metal on the chemical composition of the deposited metal, and to ensure the performance and quality of the welding head, first melt on the surface of the base metal (or the groove of the joint). Metallized transition layer (also called isolation layer). The process of depositing the transition layer is also called transition layer surfacing.

Selection of surfacing alloy Welding Wire

The correct selection of surfacing alloy welding wire can ensure that the surfacing layer exerts its good working performance, and can save alloy elements to the maximum extent and reduce the repair cost. When choosing a surfacing alloy welding wire, it is very important to meet the performance requirements of the use conditions and economic rationality. The workpiece material, batch, and the surfacing method and process to be used must also be considered.

1. Selection principle of surfacing alloy welding wire

(1) To meet the performance requirements of the parts under the workpiece conditions, select the appropriate surfacing alloy welding wire according to the different requirements of the surfacing workpiece and working conditions. Understand the working conditions (temperature, medium, load, etc.) of the surfacing parts, and identify the type of damage during operation. Choose a surfacing alloy wire suitable for this damage type. For example, the chisel-type abrasive wear of the bucket teeth of the excavator is subjected to severe impact, and the surfacing alloy welding wire that can resist impact wear should be used. .

(2) The selected surfacing material with good weldability should be easy to surfacing under field conditions and obtain a gold layer of surfacing alloy welding wire with good bonding with the matrix and no defects. Attention should be paid to the phase fusion between the surfacing alloy welding wire and the base metal. Especially in the repair of workpieces, the matrix is likely to be the original surfacing layer, and its chemical composition, microstructure and properties should be understood. When the carbon equivalent of the base metal is high, in order to prevent cracks in the process of surfacing repair, the process measures of preheating, heat preservation, slow cooling or post-weld heat treatment can be considered, and the process method of the transition layer in the surfacing can also be considered.

(3) The economy of surfacing welding The selected surfacing alloy welding wire should be the one with the highest price among the various surfacing alloy welding wires with roughly the same performance. a kind of. The economic benefits after the surfacing parts are put into use should also be considered. Especially in the repair of major equipment, the cost of surfacing or processing may be higher, but because the repair time is shortened, the economic loss of equipment downtime is reduced, or the service life of components is extended, which will also bring huge social and economic benefits.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.