Payment Type:L/C,T/T,D/P,Paypal

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU

Min. Order:100 Kilogram

Transportation:Ocean,Land,Air

Port:Shanghai,Qingdao,Shenzhen

$1.99-9.99 /Kilogram

Model No.: HP-FP

Brand: HP Plate, HP Welding

Place Of Origin: China

Specified Size: Make To Order

Packaging: Steel Frame or Wood Case

Productivity: 5000 tons

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500 tons per year

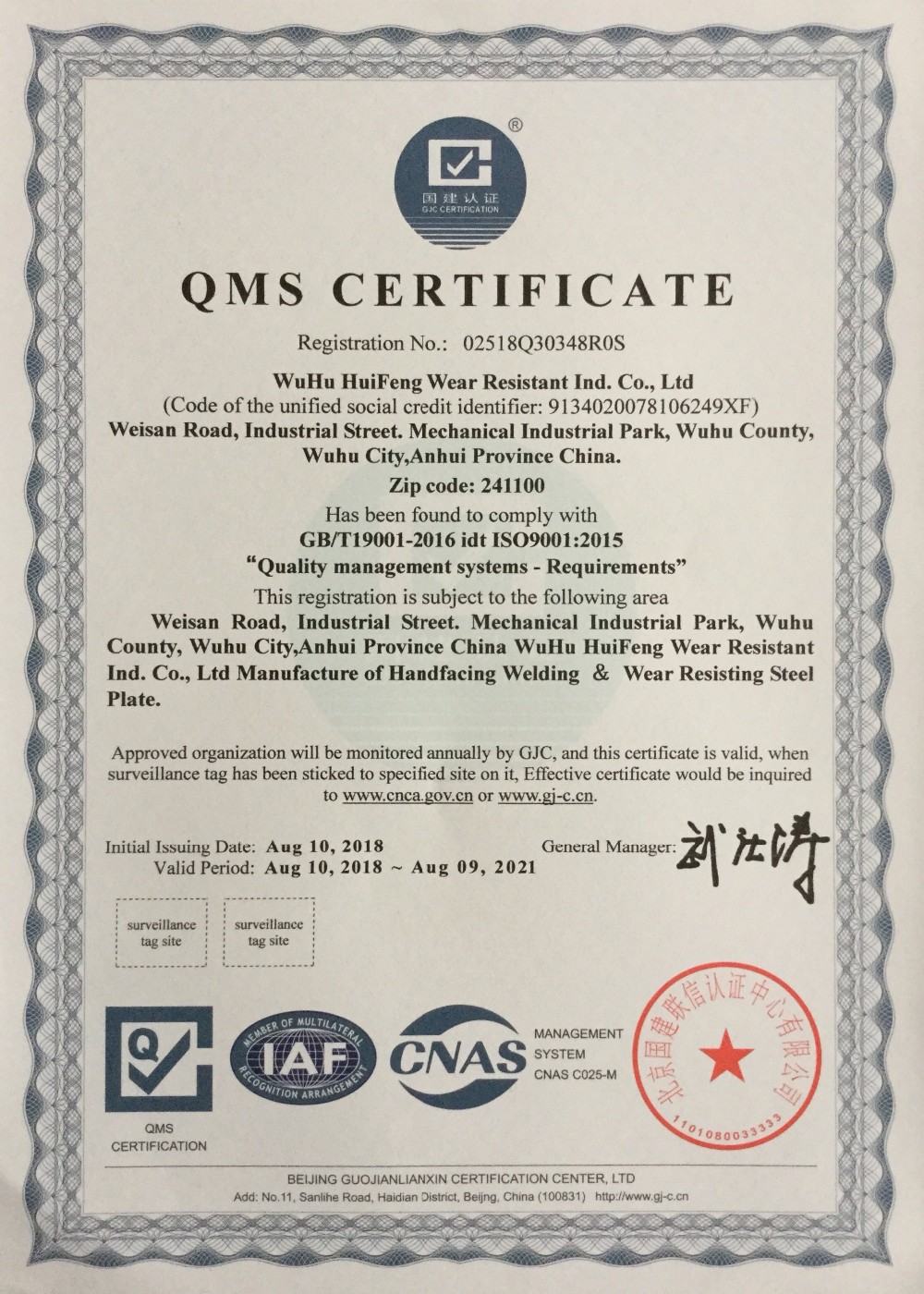

Certificate: ISO9001: 2015

HS Code: 84749000

Port: Shanghai,Qingdao,Shenzhen

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,DDP,DDU

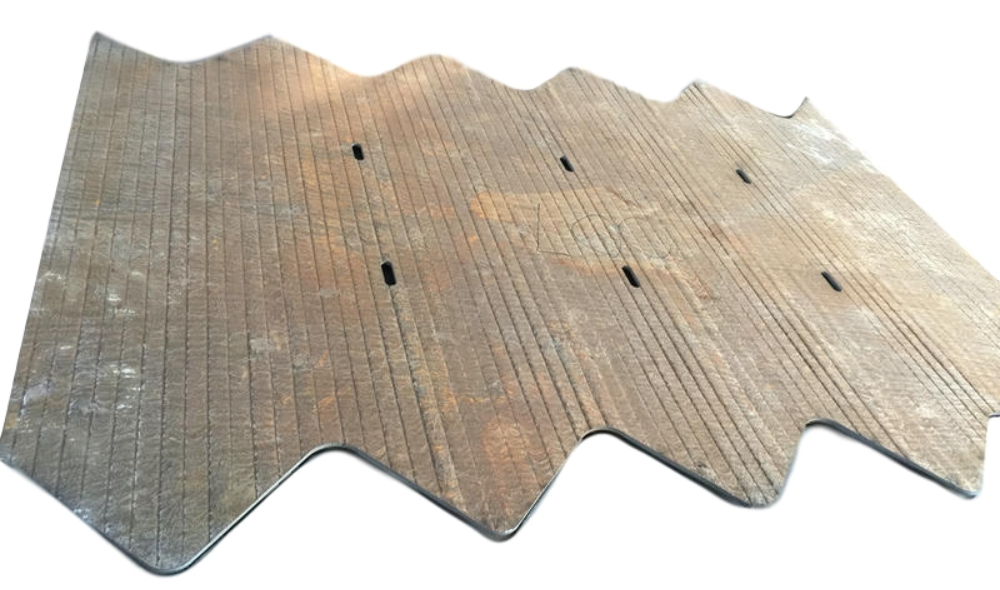

Truck Tray Liners need to afford huge heavy from delivery of iron ore and fight against abrasion. Hence, the quality Heavy Duty Truck Tray Liners is required. HP Wear Resistant Steel Plate has various application to mining site. One of typical is Truck Body Liner or Truck Bed Liners which is made by Chromium Carbide Overlay Steel Plate with substrate mild steel plate. The Wear-resisting overlayer is composed of advanced Alloy Welding which is of the excellent abrasion resistant. Besides, HP Wear Plate is also good Wear Resistant Material to make Overlay Steel Fan Blades and Tractor Shovel Front Edges

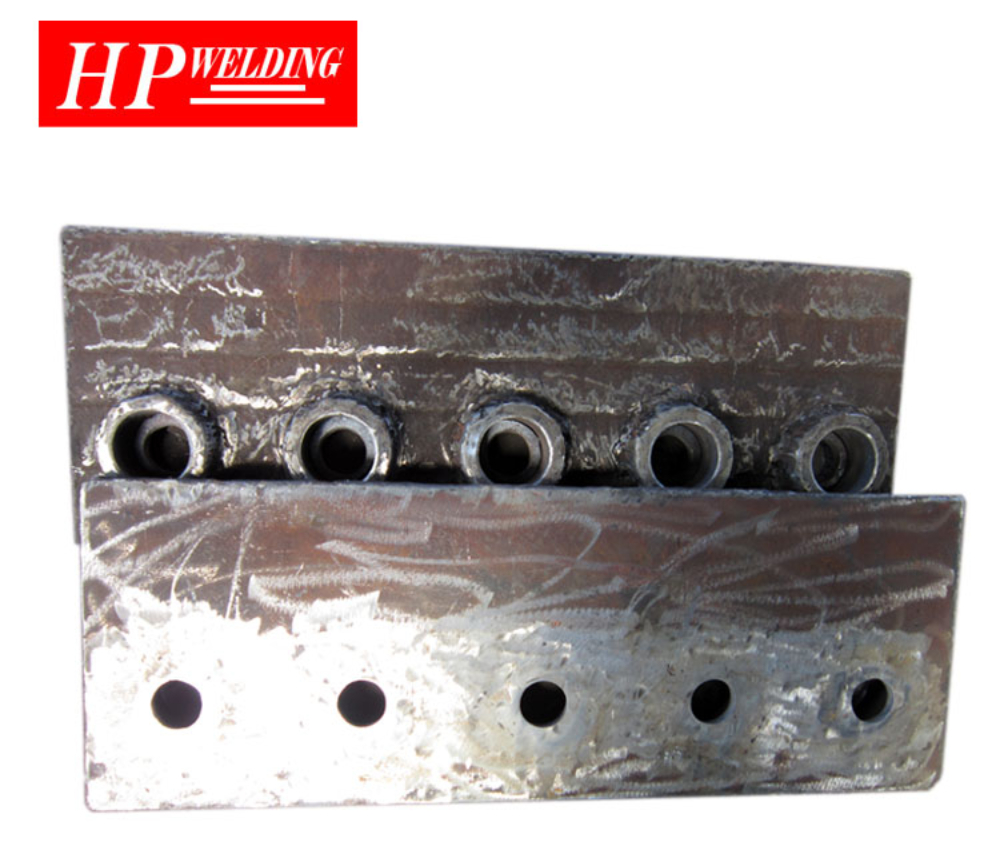

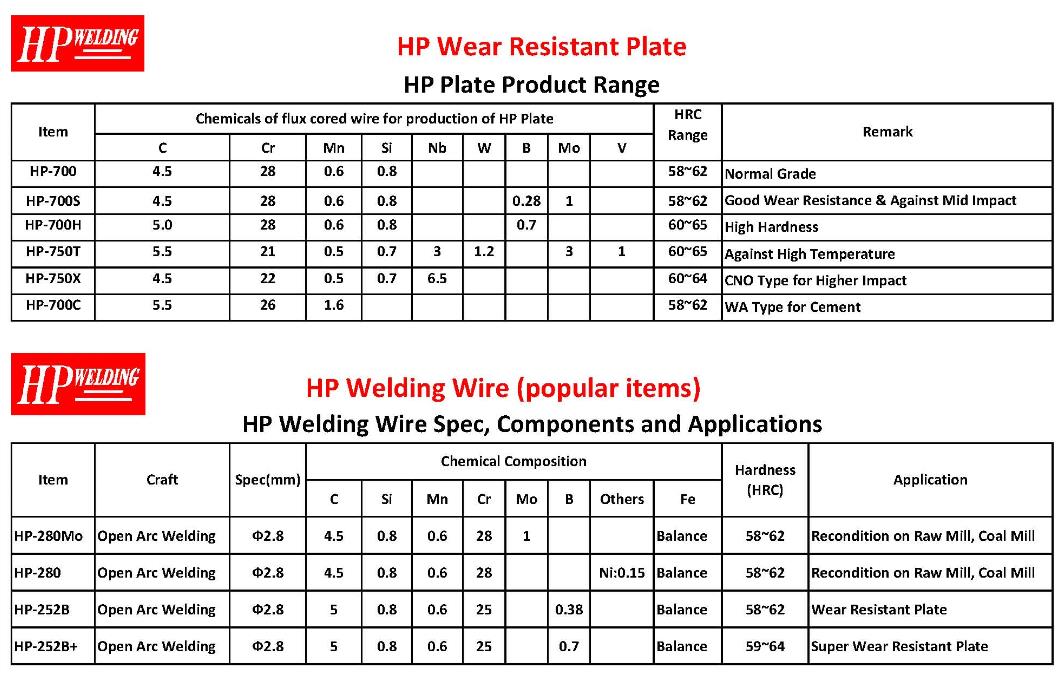

Standard Specifications of HP Wear Plate :

Packing & Delivery of Wear Plate

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 30 days after order confirmation

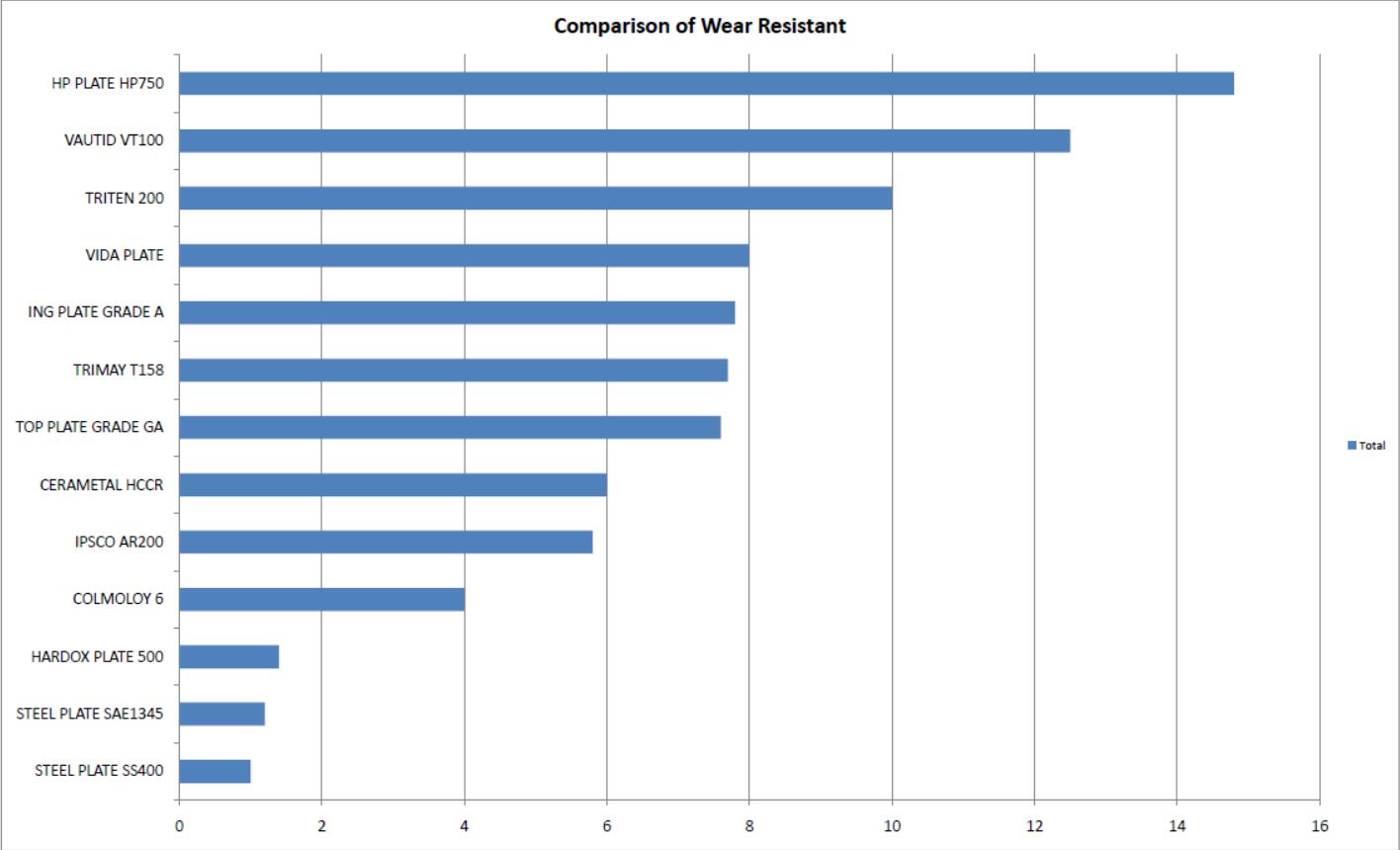

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert providing one-stop wear solution & products.

HP Wear Products Range:

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

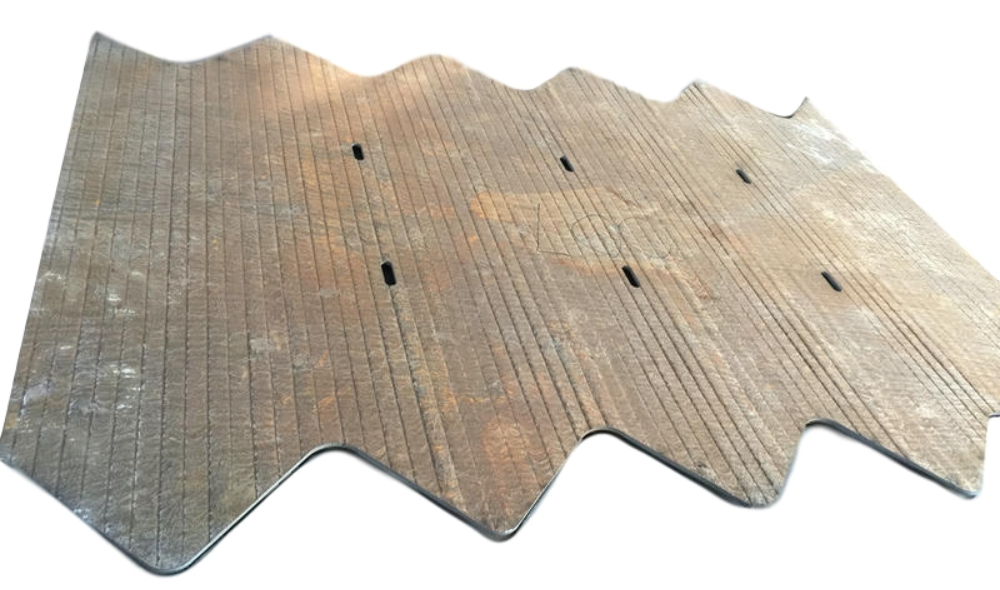

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.