Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

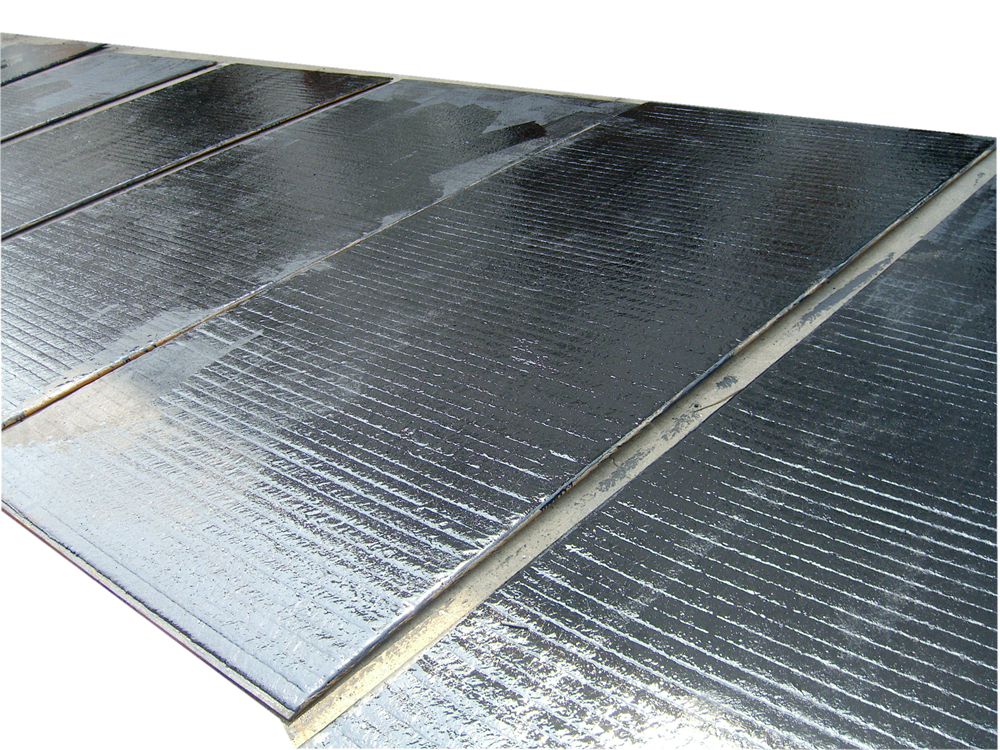

In modern large-scale industrial production, the problem of failure of mechanical components caused by wear is very serious, especially with the development of chemical, energy, transportation and other industries, in the fields of modern industry, cement, and smelting, the problem of failure caused by wear and tear is very serious. more serious. With the development of surface engineering technology, the promotion and use of large-area composite plate surfacing technology, the United States, Canada, Australia, the United Kingdom, etc. have widely used this technology in industrial production, while my country has only begun to apply it on a large scale in recent years. HP Plate is a new type of Composite Steel Plate made of new open arc surfacing flux-cored Welding Wire on ordinary Q235 Steel Plate.

The advantages of composite steel plate

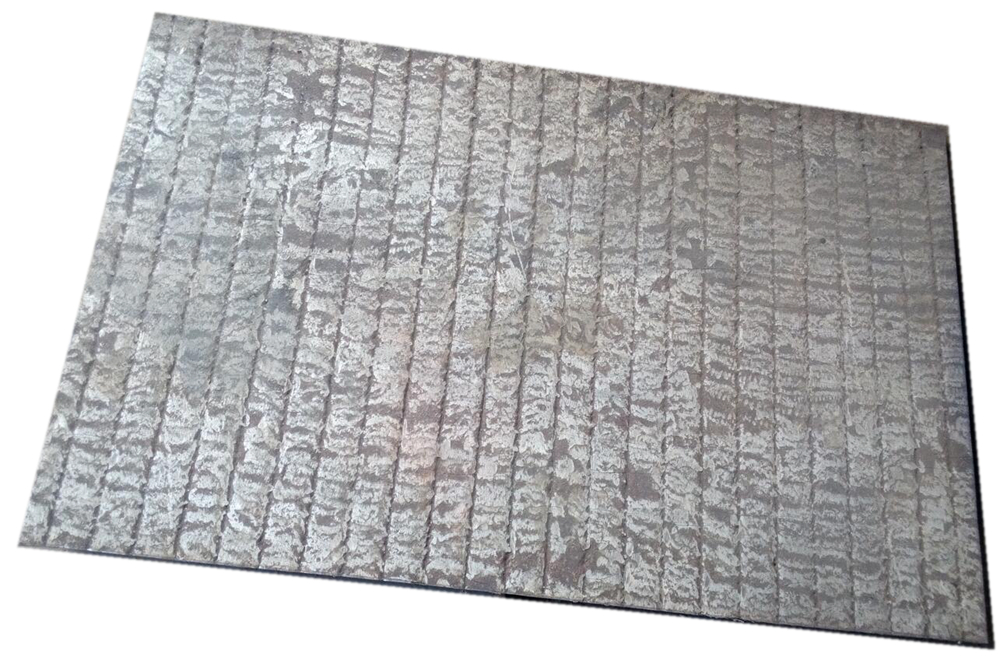

High wear resistantance

In the chemical composition of the layer, the carbon content is 3%~5%, the chromium content is as high as 20%~40%, the volume fraction of carbides in the metallographic structure is more than 50%, the macro hardness is HRC55~65, and the microscopic carbides are microscopic. The hardness is HV1400-1800, which is higher than the microhardness HV800~1200 of quartz in sand.

The energy of the composite steel plate is 5~6 times that of heat-treated steel, 5 times that of stainless steel, 5~6 times that of high manganese steel, and 11 times that of Q345 (16Mn) (experimental data of abrasive wear at room temperature). When surfacing the plate, the process method is used to control the growth direction of the carbide, so that the growth direction of the carbide is perpendicular to the flow direction of the abrasive, even compared with the casting alloy of the same composition and hardness, the energy can be increased by more than 1.3 times, which is far It is much higher than the layer prepared by spray welding and thermal spraying, and is suitable for dust and abrasive wear under the working conditions of dust concentration not greater than 3kg/m³ and airflow speed not greater than 25m/s.

Good impact resistance

The substrate of the composite steel plate is a ductile material such as low carbon steel or low alloy steel, which reflects the superiority of bimetal. The layer resists the wear of the abrasive medium, and the base plate bears the load of the medium, so it has good impact resistance and can withstand the impact and wear under working conditions such as high drop hoppers in the material conveying system.

Easy processing performance

The composite steel plate can be cut, leveled, holed, bent and curled into shapes such as flat plates, arc plates, cone plates, and cylinders. The cut composite panels can be made into various forms of engineering structural parts or components by tailor welding. Composite panels can also be hot-pressed into complex shapes with molds. The composite steel plate can be fixed on the equipment by means of bolts or welding, which is convenient for replacement and maintenance.

Good cost performance

Although the manufacturing cost of clad steel plate is high, it can prolong the service life of components, so maintenance costs and downtime losses are greatly reduced. High equipment utilization means high production efficiency and enterprise economic benefits, and its cost performance is higher than that of ordinary materials. About 2 to 4 times. As the material handling volume increases, the wear becomes more serious, and the impact on the operation rate is greater, and the use of suitable clad steel plates will produce more obvious economic benefits.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.