Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

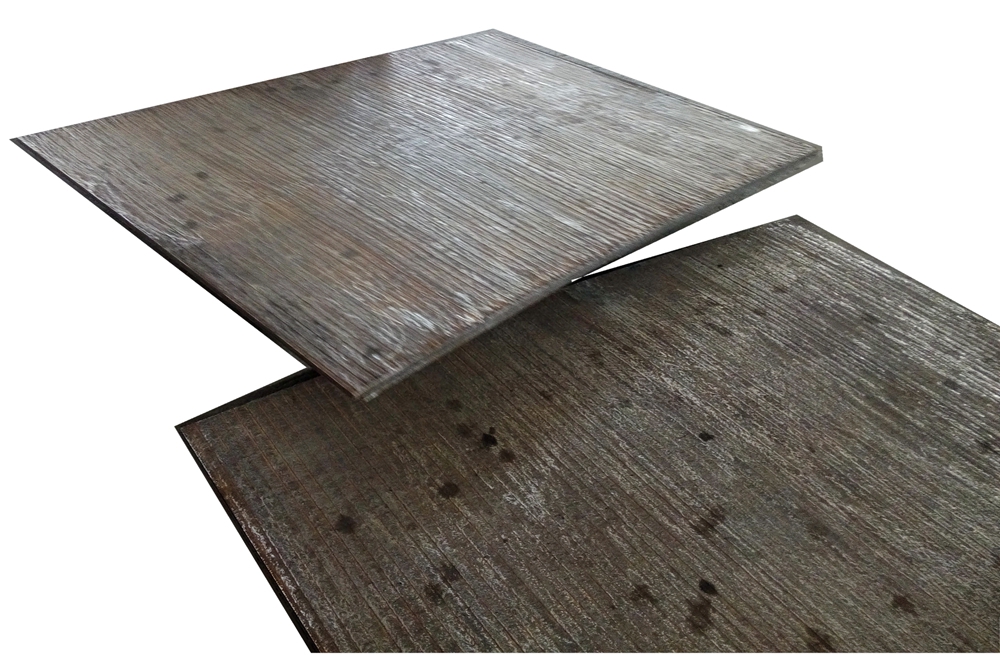

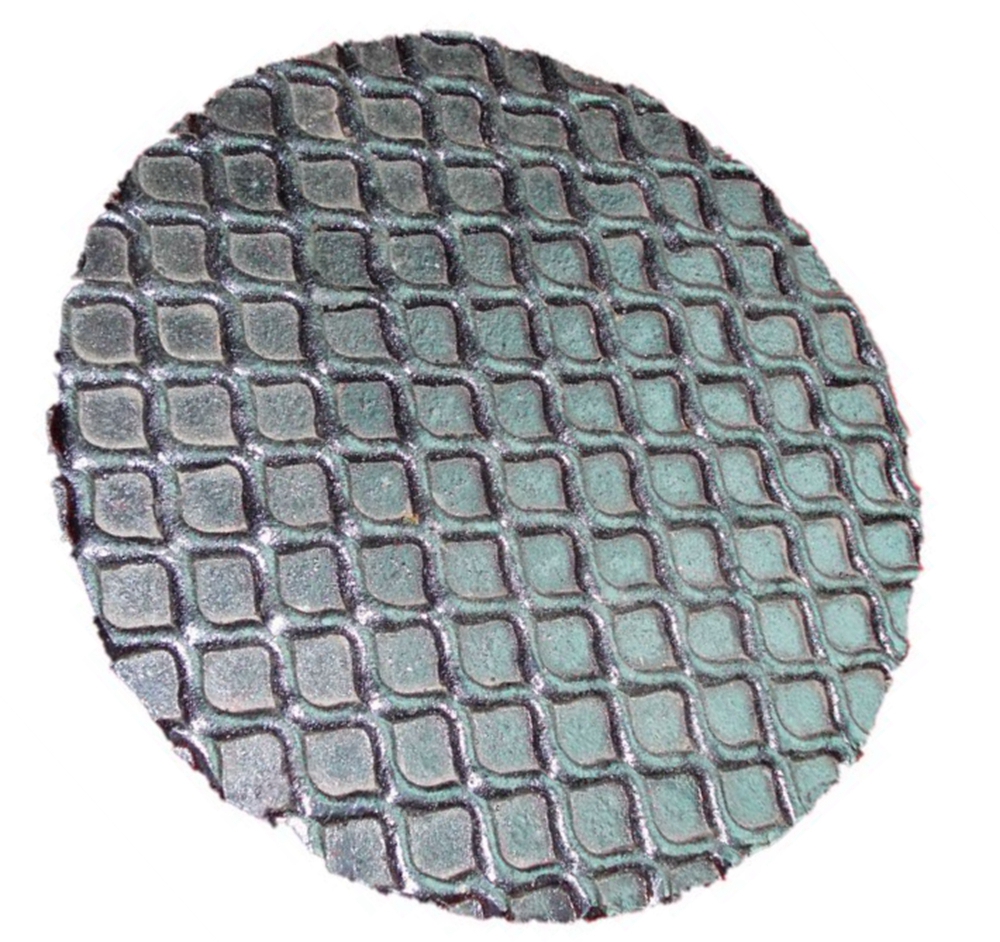

Processing of Hard Surfacing Abrasion Resistant Steel Plate

The surfacing Wear Plate can be welded into various structural parts or components through the welding of the base layer Steel Plate. A plasma cutting gun is used to punch holes in Wear-resistant Composite Steel Plates, and bolts are used to fix them.

It is fixed on the protected equipment for easy maintenance and replacement. Welding wear-resistant Chromium Carbide Steel Plates have high hardness and require plasma cutting. According to the different size and shape requirements of users, we can provide wear-resistant plates of corresponding sizes and shapes.

Users can also purchase the entire wear-resistant plate and cut it by themselves. According to the hardness and thickness of different wear-resistant steel plates, the minimum bending diameter is different. Usually, the minimum bending diameter is ≥350mm, and it can be made into flat plate, arc plate, cone plate and cylinder. During reel processing, the bending direction should be consistent with the direction of the weld bead as much as possible, especially for small diameter bending, which needs to be bent according to the requirements of the supplier!

Features of surfacing wear plate:

1. Improve economic efficiency: improve equipment operation rate, reduce production downtime and maintenance loss, increase production capacity and increase efficiency.

2. Reduce production costs: reduce the number of workers, long-term benefits from one investment, and high cost performance.

3. Improve the production environment: block running, dripping and leaking, avoid environmental pollution, and is conducive to the cleanliness of the factory environment.

4. Protect the health of workers: reduce the probability of workers working in harsh environments, reduce high-altitude and narrow space operations, and reduce work intensity.

5. Significant social benefits: reduce the waste of cast alloy plates and ordinary carbon plates, save the amount of precious alloys, and scientific and technological progress brings comprehensive social benefits.

Wear-resistant plate surfacing equipment is a new type of modern composite Wear-Resistant Steel Plate material, which has been popularized and used in industrialized countries since the 1960s. With the development of science and technology in our country and the needs of market economy development, the special properties and practical economic value of wear-resistant surfacing clad steel plates are gradually being managed by some large industrial and mining enterprises with advanced consciousness.

It has been recognized and used by the users, and has created considerable economic benefits for the enterprise.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.