Payment Type:L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA

Min. Order:100 Kilogram

Transportation:Ocean,Land,Air

Port:Tianjin,Shanghai,Qingdao

Model No.: HP-700RL

Brand: HP Plate

Place Of Origin: China

Processing Service: Moulding, Cutting

Specified Size: Make To Order

Packaging: Steel Frame or Wood Case

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500 tons per year

Certificate: ISO9001: 2015

HS Code: 4016999090

Port: Tianjin,Shanghai,Qingdao

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA

Abrasion Resistant Rubber Liners are used in grid type, overflow type, multi-warehouse-type ball mill. Rubber Liner is mainly applied to wet grinding process, and now dry grinding which required strict metal impurities (iron) has also been applied.

Our commitment to ongoing design improvements and high service offerings has resulted in the development of ball mill liners that extended periods between shut downs and improve grind efficiency.

Cement Ball Mill Liner Plate by HP Wear Resistant Group is customized to your application using state-of-the-art software-driven designs. This means that your ball mill lining solution precisely fits into your application.

Ball Mill Spare Parts, Abrasion Resistant Rubber Liner, Shell Lifter Bar Rubber Liner are what we supply to meet your requirement.

Key Specifications Of Rubber Product:

Unit Standard Tensile strength Mpa 17 Elongation % 420 Permanent Deformation % 10 300% Tensile Strength Mpa 11 Impact Elasticity % 45 Wear Reduction cm³/1.61km 0.15 Shore (a) Hardness 65±5 Aging Coefficient (70℃*48h) 0.8

Performance Index

Ball Mill Liner components:

Our ball mill liners solutions can be fitted with lifter bars, shell plates and head plates. We utilise Hardox wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

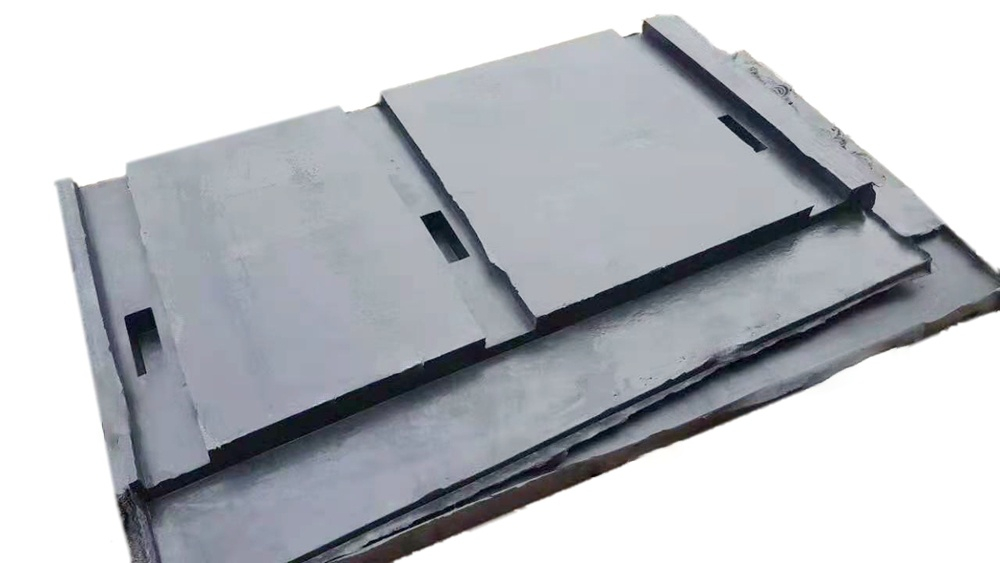

Shell Plates

Shell plate thickness can vary, which helps both in balancing mill capacity as well as extending ball mill liner life. For arduous milling applications, or where drilling patterns produce shell plates that are too wide, thus exposed to high wear, shell plates with Hardox strips can be utilised.

Lifter Bars

Available in a range of profiles and dimensions, lifter bars increase the efficiency of the milling operation by maximising the agitation of the ore. The impact and abrasion resistance of these bars is maximised by Hardox steel along the leadings edges of these components. With a high-quality attachment system, lifter bars are easy to install to the ball mill liner.

Head Plates

We custom-design head plates according to each ball mill to ensure maximum performance and lifespan. Most commonly, our head plates are built from high-quality, specially-formulated rubber. In arduous ball mill applications, Hardox strips can be fitted to the head plates to increase their operational life.

Grate Plates

Grate plates are available in a range of aperture sizes and configurations. Internal frames are designed for different mill loads, and it is possible to use semi-overflow designs in order to control the pulp level in the mill. Different options for extending plate life exist as required by your application, such as built-in lifter bars.

Pulp Lifters

Manufactured with a rubber-lined fabricated steel base, our pulp lifters use high-quality designs that ensure a correct volumetric flow of the pulp. Rubber wear plates designed to be bolted onto the high-wear areas of the ball mill liner improve the performance life of your mill.

Central Cones

These components assist in the controlled discharge of the material, maintaining mill capacity across the operation. Cones are provided in segments, which are then assembled inside the mill. This enables easier handling and manageability.

Trunnion and Bell Mouth Liners

Manufactured with a fabricated steel base that is then rubber lined. Loose steel-reinforced rubber liners are also used in larger trunnions.

Filling and Support Segments

Extend the wear liner to the corners of your ball mill and scrubber, enabling a clean, smooth lining across the ball mill liner.

Key Specifications Of Rubber Product:

Unit

Standard

Tensile strength

Mpa

17

Elongation

%

420

Permanent Deformation

%

10

300% Tensile Strength

Mpa

11

Impact Elasticity

%

45

Wear Reduction

cm³/1.61km

0.15

Shore (a) Hardness

65±5

Aging Coefficient (70℃*48h)

0.8

Packing & Delivery

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 4 weeks after order confirmation or to discuss

Company Information

We are specialized in designing and manufacturing wear resistant products including anti-abrasion rubber lining, polyurethane lining, wear resistant steel products, ceramic liner, conveyor accessories, etc. Our products are widely used in bulk material handling industries including coal mine, steel plant, power generation, cement plant, metallurgy, chemical and other fields.

HP Wear Solution Products Show Case:

HP Factory Laboratory

Performance Index

Q1: Is customization available?

A: We support customization according to your request.

Q2: How long is your delivery time?

A: 3~4 weeks. We have key raw materials stock at need of urgent order, and the priority will be given when necessary.

Q3: Can we visit your factory?

A: Yes, you are welcome to visit us. Just share us your itinerary when available.

Q4: What is the quality control on products.

A: Every product will be inspected strictly before delivery

Q5: Are the samples free of charge?

A: Yes, free sample is available or to discuss.

Q6: What information is required to proceed with purchase order?

A: It would be great supportive to us if technical drawings provided in details.