Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

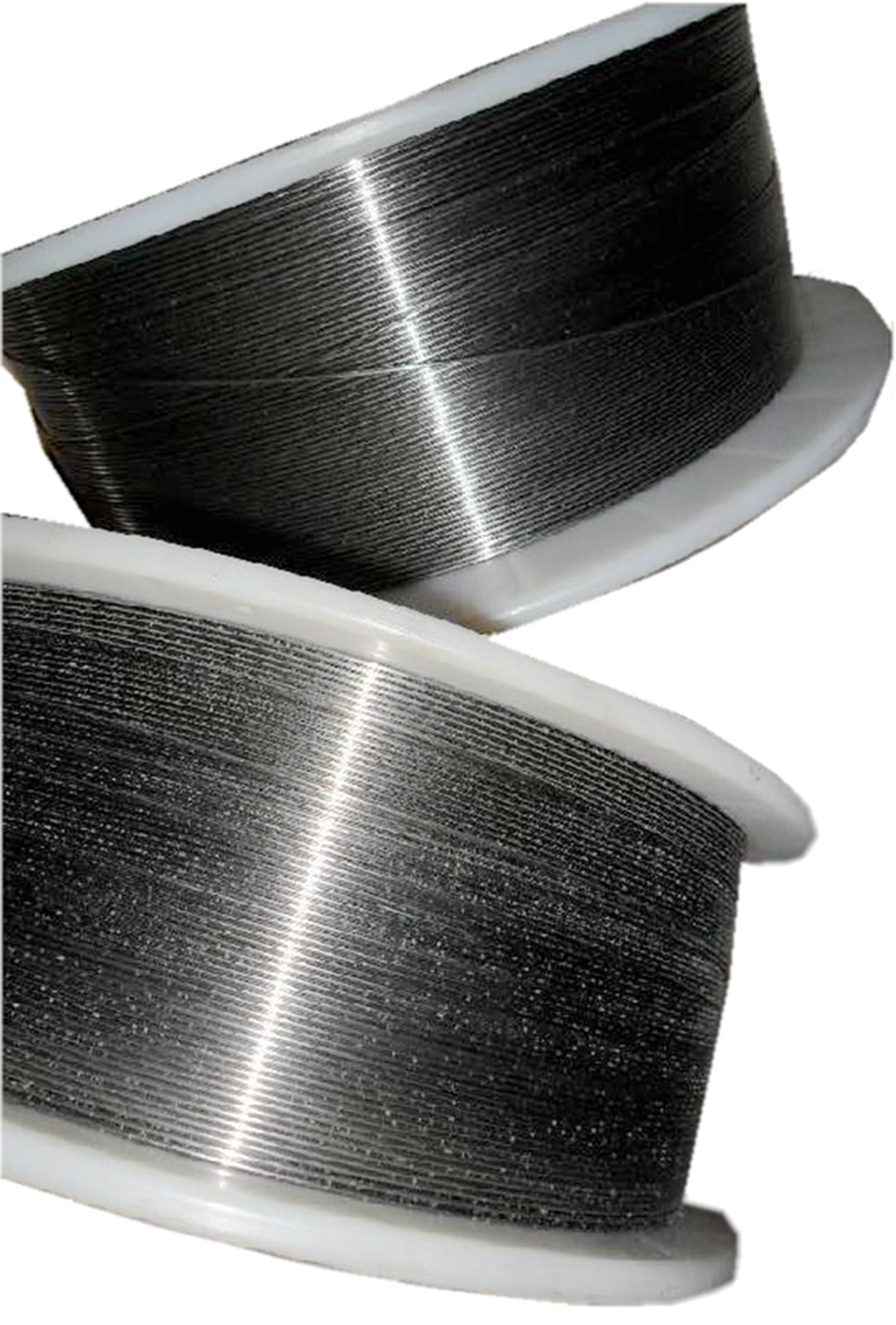

According to our experience, the first level of product quality control is the selection and control of raw materials. As far as the situation in the industry is concerned, large-scale enterprises and famous brand enterprises generally use the products of large domestic steel mills. However, small enterprises and some enterprises use surrounding steel mills and even steel strip products of unknown origin. We hereby suggest and also call on the wear-resistant wire industry to use products from large steel mills as much as possible. HP Welding Wire has been using Baosteel's special steel strip for flux-cored welding wire.

The raw material of the steel strip of large steel mills has stable chemical composition, especially the control of impurity content is relatively stable, and the surface of the steel strip has no defects such as burrs. The steel strip with stable quality and excellent quality can ensure the stability of the overall chemical composition of the welding wire, realize the original design requirements, and also ensure that the wire can be discharged smoothly when the user uses it, and it is not easy to cause problems such as wire blocking and wire jamming.

Although Baosteel products and distributors will provide the chemical composition quality inspection documents of each batch of steel strip products. However, we still recommend that wear-resistant welding wire companies check again when they are put into storage. Although the results of the self-test are basically in line with the report provided by the manufacturer. However, we have also found that the results are quite different through self-inspection. After the round-robin investigation, we finally found that there was an error in the upstream dealer's entry and exit links. If the inspection control is not set in the process of raw material storage, then this batch of steel strips will be processed into finished welding wire, and the problem will not be found until the inspection and control of the finished product, and the direct loss to the enterprise will be more serious.

Compared with the quality of steel strips, the quality control of alloy powder raw materials is a more difficult and complicated task. Wear-resistant welding wire uses a large number of alloy powders, a large number of specifications, and a large number of technical parameter requirements. As for suppliers, so far, there is no company that can supply all alloy powders at the same time. In addition, due to scale factors, as well as quality awareness, the quality control of most alloy powder manufacturers falls far short of the needs of wear-resistant wire manufacturers.

Solving the problem of alloy powder quality control is a long and difficult task. Our lessons and experience are that, first of all, we must strictly control the warehousing inspection, and we must carry out the warehousing inspection for each batch. This is the most effective and powerful measure. Warehousing inspection work, start with the main element inspection, and then carry out the impurity inspection work after the main element inspection is proficient.

Secondly, the choice of suppliers should be expanded from domestic to overseas. So far, more than 50% of our alloy powder raw materials are imported products. Here, for some alloy powders, the procurement cost is lower than that of domestic suppliers. Even if some alloy powders are slightly higher than domestic suppliers in terms of procurement cost, they are superior to domestically supplied products in terms of product purity, particle size, impurity content, loose packing ratio and other technical perspectives. Value, value for money range.

According to our experience, customers not only pay attention to the product performance indicators such as hardness and composition of wear-resistant welding wire, but also pay more attention to the entire production process of wear-resistant welding wire, especially the quality control work. In terms of raw materials, good quality control, practical implementation of raw material storage testing, and selection of raw materials from well-known manufacturers will win the trust and goodwill of customers.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.