Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product description

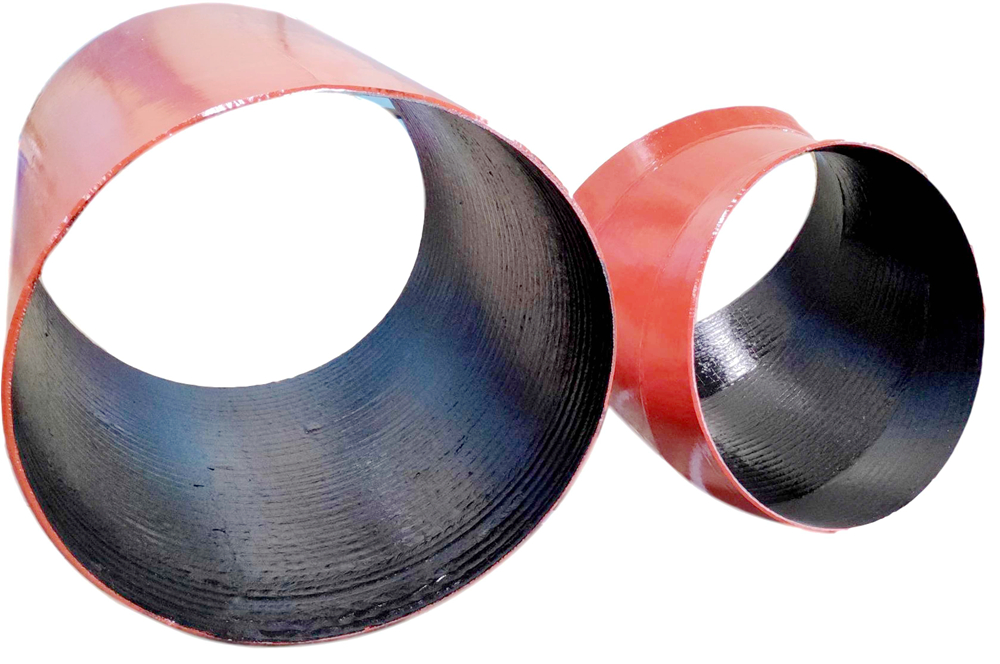

The bimetal surfacing pipe is mainly manufactured by surfacing welding technology. The mechanical part of the surfacing pipe manufacturing equipment is designed reasonably, and the electrical uses the key surface to input data, which can realize the free connection with other equipment and the welding machine; the walking speed can be adjusted at any time according to needs. The welding bead can be automatically arranged and continuous surfacing. The wire feeding adopts automatic wire feeding. The swing speed and width of the welding gun can be set by themselves; the height of the welding gun during the welding process adopts an independent automatic tracking system to improve the overall work efficiency.

Product Usage

Metallurgy, power industry transportation of coal powder, ash, mud, lime gypsum slurry, etc. require a large amount of metal pipelines every year.

Mine: Mine filling, ore concentrate and tailings transportation cause serious wear on pipelines. The service life of ore powder transportation pipelines used in the past, such as Panzhihua and Daye Mine, is less than one year. Changing to this pipe can increase the service life by about 5 times.

Coal: Coal preparation and long-distance pipeline coal transportation generally adopt wet transportation, and the transportation pipe is required to be corrosion-resistant. The pipe can be used as a long-life transportation pipe with considerable economic benefits.

Craftsmanship

The bimetallic surfacing pipe produced by HP has undergone a series of processing and transformation, and its products are of very good quality. The problem often encountered in surfacing welding is cracking. The methods to prevent cracking are mainly preheating before welding and slow cooling after welding. Surfacing effect.

For example, the hardness and heat resistance of the surfacing layer are related to the welding current and arc length. If the current is large and the arc is long, the alloy elements are easy to burn, and the current is small and the arc is short, which is beneficial to the transition of alloy elements. Some surfacing metals can use different heat treatment methods with different hardness. The hardness and chemical composition of the surfacing metal generally refers to the surfacing metal of more than three layers.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.