Payment Type:L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm:FOB,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Kilogram

Transportation:Ocean,Land,Air

Port:Shanghai,Qingdao,Shenzhen

Model No.: HP-145

Brand: HP Plate, HP Welding

Standard: Aisi, Astm, Bs, Din, Gb, Jis

Place Of Origin: China

Species: Drawn Wire

Application: Construction, Manufacturing

Whether Alloy: Is Alloy

Tolerance: ±1%

Processing Service: Welding

Standard Diameter: Φ1.2, Φ1.6, Φ2.8, Φ3.2

Package Standard 1: 15kgs/Reel

Package Standard 2: 250kgs/Drum

Packaging: In Drum or In Reel

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10 tons per day

Certificate: ISO9001: 2015

HS Code: 8311200000

Port: Shanghai,Qingdao,Shenzhen

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CIF,EXW,FCA,CPT,CIP

Flux Cored Chromium Welding Wire enables a Cr-Mo-V alloyed deposit for semi automatic and automatic surfacing. It is good for repair of manganese steel Buckets and shovels, high tensile tools & dies, clutches, crane wheels, earthmoving undercarriage parts, gear wheels, etc with good resistance to tempering and good crack resistance.

HP Welding manufactures an extensive range of High Chrome Flux Cored Wire and metal cored hardfacing consumables. We offer welding wires for low, medium and high alloy hardfacing, which provide the ultimate protection against various types of wear, including abrasion, erosion, impact, mechanical fatigue, and more.

Equivalent to ESAB Welding Wire, HP FCAW Welding Wire is ideal to produce buffer layer before hardfacing with chromium cast iron. The wire is ideal for the applications like repair work on railway frogs and crossings, hammers, bars, cones and jaws for crushers.

For example, Hard Surface Welding Wire HP100Mo has good ability of a material to increase its surface hardness under the effect of impact or high pressure. In general, this increases wear resistance.

We offer welding wires for low, medium and high alloy hardfacing, for mild and stainless steel fabrications, and nickel and cobalt base wires. Diameters range from 1.2 mm to 4.0 mm, using our own manufacturing technology. In addition to cored wires, our range of consumables includes stainless welding wires and tubular welding electrodes.

We manufacture an extensive range of flux cored and metal cored hardfacing consumables. We offer welding wires for low, medium and high alloy hardfacing, which provide the ultimate protection against various types of wear, including abrasion, erosion, impact, mechanical fatigue, and more. Click below to view our range of flux cored wires and metal cored wires for hardfacing.

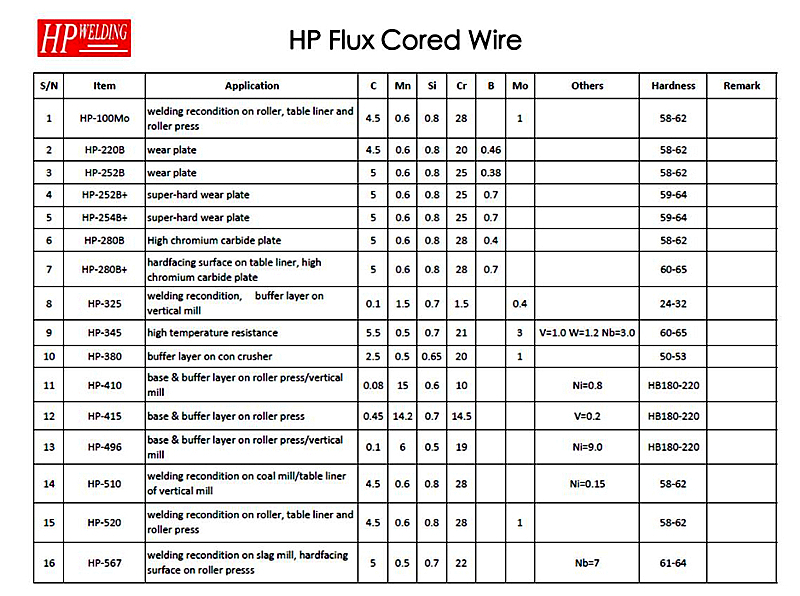

Standard Specifications Of HP Flux Cored Welding Wire:

Packing & Delivery Of Flux Cored Wires

Packing Way: Opt.1_5kg By Reel/Opt.2_ 250kg By Drum

Delivery Time: 20 days after order confirmation

Micro Structure On Welding Deposite

Test Data On HP Flux Cored Wire

HUIFENG Wear Resistant Group is a professional manufacturer commited to offer of wear products since 1989.

We supply wear plate, hardfacing pipe, wear parts, flux cored welding wire, wear resistant casting material & other wear solution.

We have been serving Cement Industry, Mining Site, Power Plant, Steel Mill, Glass Industry, etc... for over 30 years. As the great milestone during our growth, our group set up the joint venture with Vautid GmbH to produce the first class of wear products in China. HP Group is under ISO9001 quality management, and products applied to SGS certification.

Q1: Can I have a sample for testing?

A: Yes, the sample could be offered at your request.

Q2: Can I add my logo on the boxes/cartons?

A: Sure, we are capable of R&D, OEM and ODM are available from us.

Q3: What are the benefits of being a distributor?

A: The special discount and also marketing protection.

Q4: How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting or installation process, as well as aftermarket support.

Q5: Can we mix items in full container?

A: Yes. We ship our products in bulk, usually 40 feet high cube containers, but 20 feet containers are also acceptable.

Q6: Can I have a visit to your factory before the order?

A: Sure, welcome your visit to our factory.