Payment Type:L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm:FOB,CFR,CIF,EXW,FCA,CPT,CIP

Min. Order:100 Kilogram

Transportation:Ocean,Land

Port:Shanghai,Tianjin,Qingdao

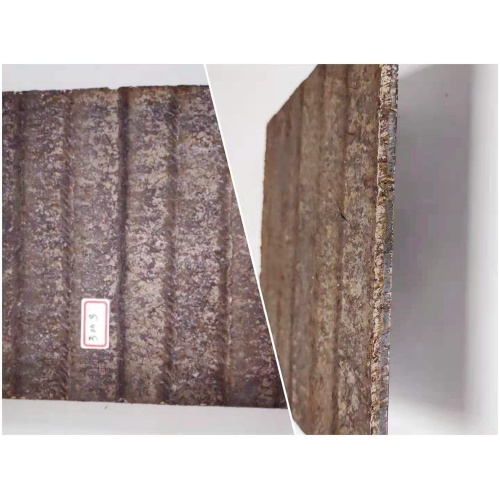

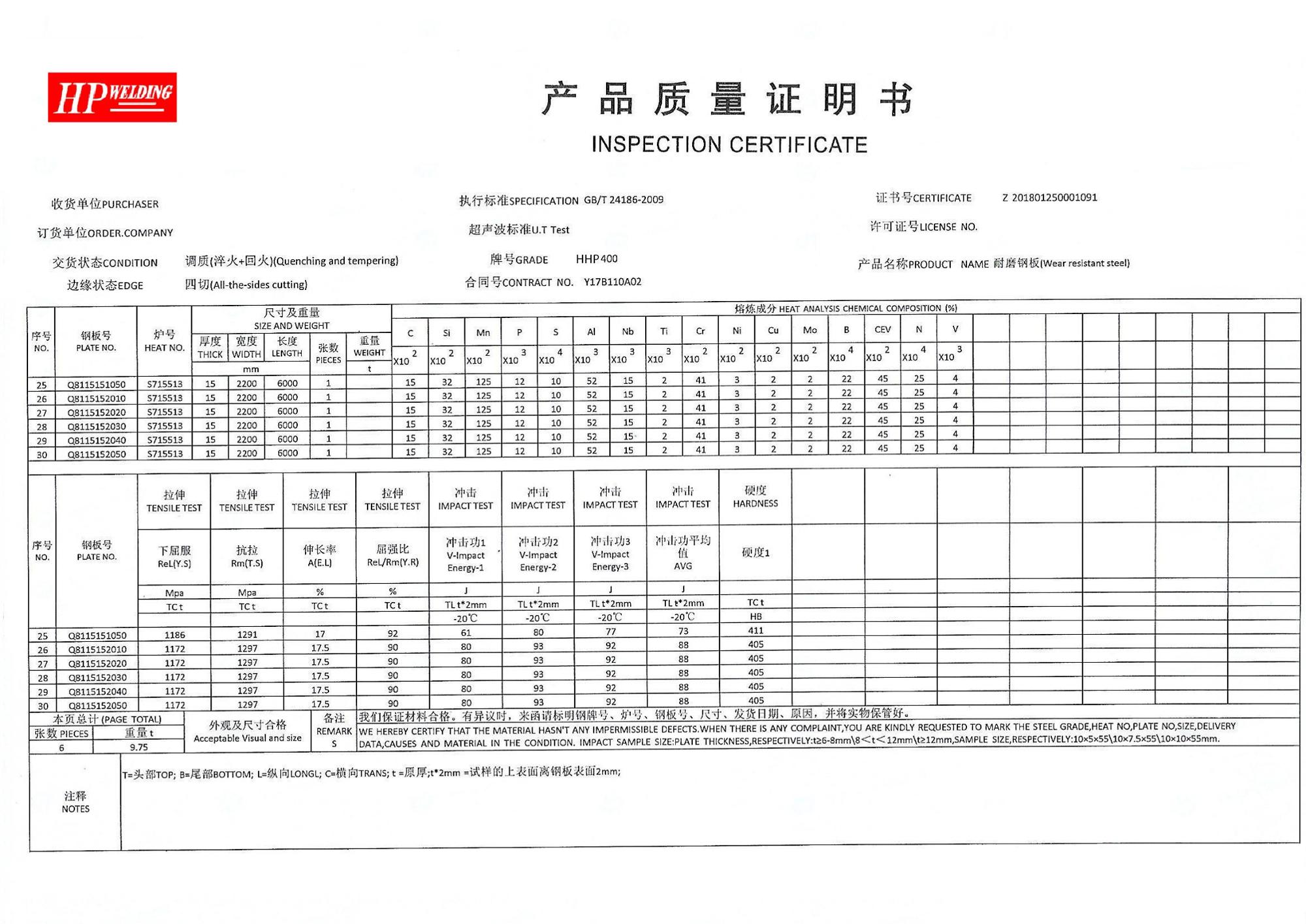

Model No.: Wear Plate-HP700

Brand: HP Plate, HP Welding

Packaging: Steel frame & steel belt fastened

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 500 tons per year

Certificate: ISO9001: 2015

HS Code: 72109000000

Port: Shanghai,Tianjin,Qingdao

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by the president Mr. Zhang Kun-Mou. Using the world-famous Japanese KURIMOTO hardfacing welding patented technology, with welding materials produced by Vautid GmbH, HP Plate has become the most successful experts specializing in production and sales of hardfacing welding overlay plates.

HP Product Range:

HP Laboratory

HP Certification:

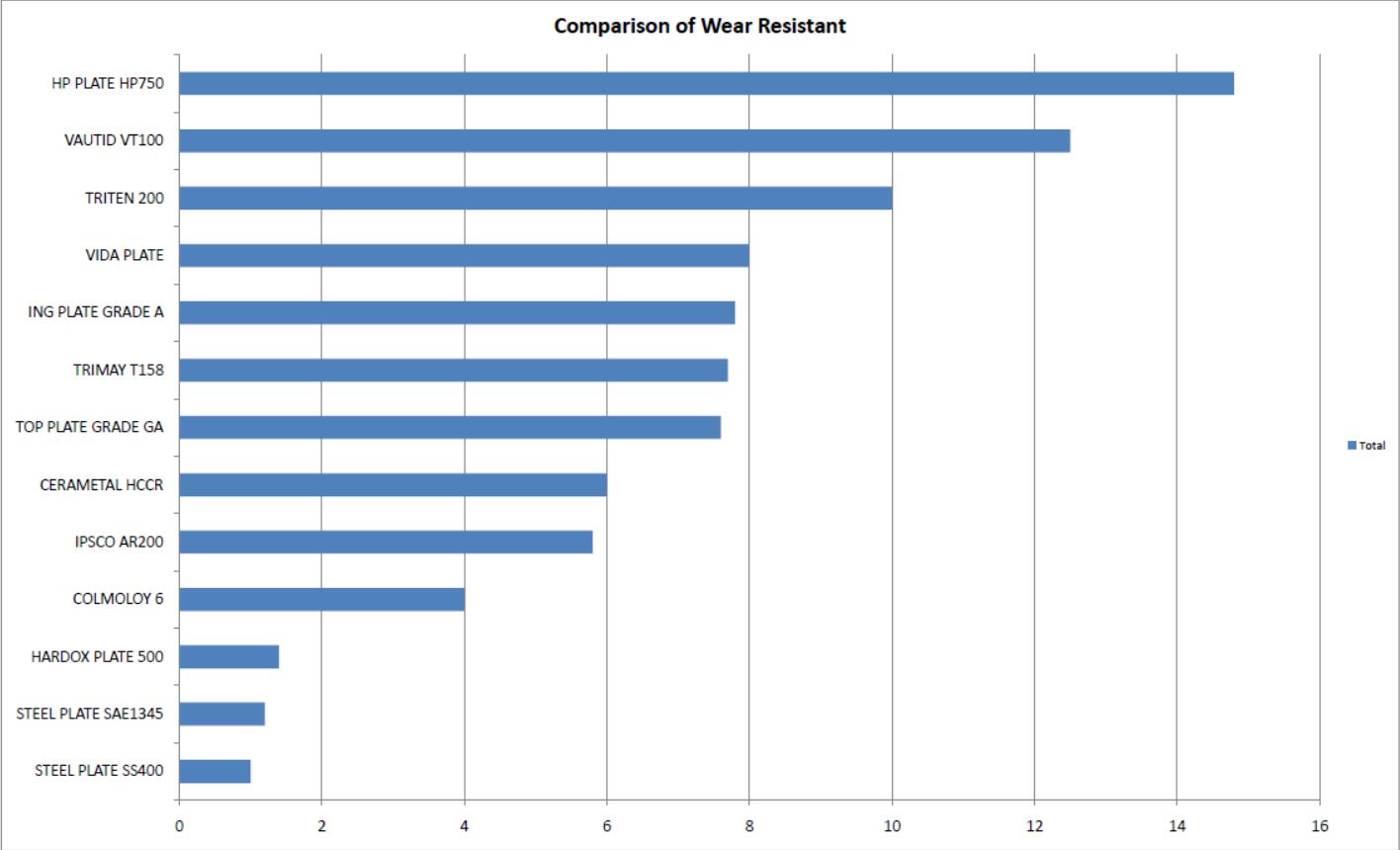

Comparison_HP Plate vs Other Plate

Contact us:

1) Wear Resistant Plate & Hardfacing Pipe

2) Fabriction parts including Liner, Dredging Pipe & other customised parts

4) Vertical Mill Components (Rollers & Table Liners)

5) HP Wear Plate & Hardfacing Pipe

6) HP Wear Parts

7) Flux Cored Wire & Welding Recondition